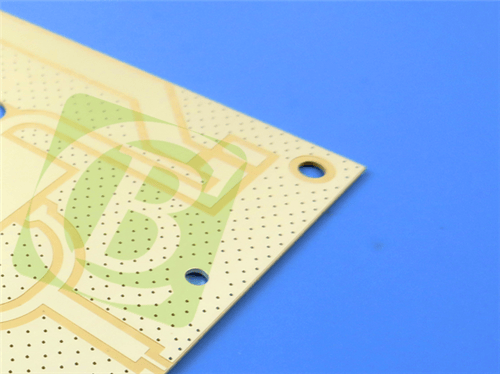

RO3210 2-Layer 0.6mm High-Frequency PCB – 20mil Ceramic Woven Glass with Immersion Gold for Automotive Radar and 5G Base Stations

1.Introduction to RO3210 2-Layer 0.6mm PCB

Rogers' RO3210 high frequency circuit materials are ceramic-filled laminates reinforced with woven fiberglass, engineered to deliver exceptional electrical performance and mechanical stability with one distinguishing characteristic - significantly improved mechanical stability. RO3210 laminates uniquely combine the surface smoothness of non-woven PTFE laminates, enabling finer line etching tolerances, with the rigidity of woven-glass PTFE laminates. These advanced materials can be fabricated into printed circuit boards using standard PTFE circuit board processing techniques, making them both high-performing and practical for manufacturing.

2.Key Features

Dielectric constant: 10.2 ± 0.5

Dissipation factor: 0.0027 at 10GHz

Coefficient of thermal expansion matched to copper: X-axis 13 ppm/°C, Y-axis 13 ppm/°C, Z-axis 34 ppm/°C

High decomposition temperature: 500°C (TGA method)

Enhanced thermal conductivity: 0.81 W/m·K

Flammability rating: UL 94 V-0 standard

3.Benefits

Woven glass reinforcement improves rigidity for easier handling

Uniform electrical and mechanical performance ideal for complex multi-layer high frequency structures

Low in-plane expansion coefficient matched to copper enables reliable surface mounted assemblies

Suitable for use with epoxy multi-layer board hybrid designs

Excellent dimensional stability ensures high production yields

Superior surface smoothness allows for finer line etching tolerances

4.PCB Construction Details

| Parameter | Specification |

|---|---|

| Base Material | RO3210 |

| Layer Count | 2-layer |

| Board Dimensions | 54.5mm × 50mm (±0.15mm) |

| Min. Trace/Space | 5 mil / 8 mil |

| Min. Hole Size | 0.3 mm |

| Blind Vias | No |

| Finished Board Thickness | 0.6 mm |

| Finished Cu Weight | 1 oz (outer layers) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Gold |

| Top Silkscreen | White |

| Bottom Silkscreen | No |

| Top Solder Mask | Blue |

| Bottom Solder Mask | No |

| Electrical Test | 100% tested prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper_layer_1 - 35 μm

Rogers RO3210 Core - 0.508 mm (20mil)

Copper_layer_2 - 35 μm

6.PCB Statistics:

Total Pads: 23

Thru Hole Pads: 15

Top SMT Pads: 8

Bottom SMT Pads: 0

Vias: 14

Nets: 2

7.Typical Applications

Automotive collision avoidance systems

Automotive global positioning satellite antennas

Wireless telecommunications systems

Microstrip patch antennas for wireless communications

Direct broadcast satellites

Datalink on cable systems

Remote meter readers/

Power backplanes

LMDS and wireless broadband

Base station infrastructure

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide